NeXGen

Co2 Laser

Systems

Co2 Laser

Systems

CUSTOM LASER SYSTEMS would like to introduce you to the NeXGen Co2 Laser system. Being in the industry for over a decade building lasers and working on high end, rebranded imports and DIY machines. We felt there was a big gap in the difference in quality being offered. The NexGen Laser system bridges the gap between high-end laser systems (like Trotec, Epilog and Universal) and the rebranded generic Chinese imports that are currently available. NeXGen Laser Systems provides unprecedented build quality and the latest technology available today. Making it faster, more precise and with less maintenance.

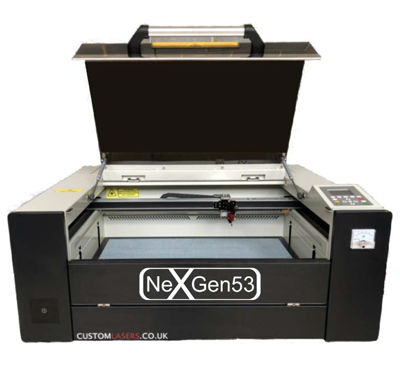

NeXGen53

| Work Area 500 x 300 |

| Wattage 40 to 60 watts |

| Max Engraving Speed 1200 mm/s |

| Max Scanning Precision 4000dpi |

| Location accuracy 0.01 mm |

| Machine Size 900 x 710 x 430 (without stand) |

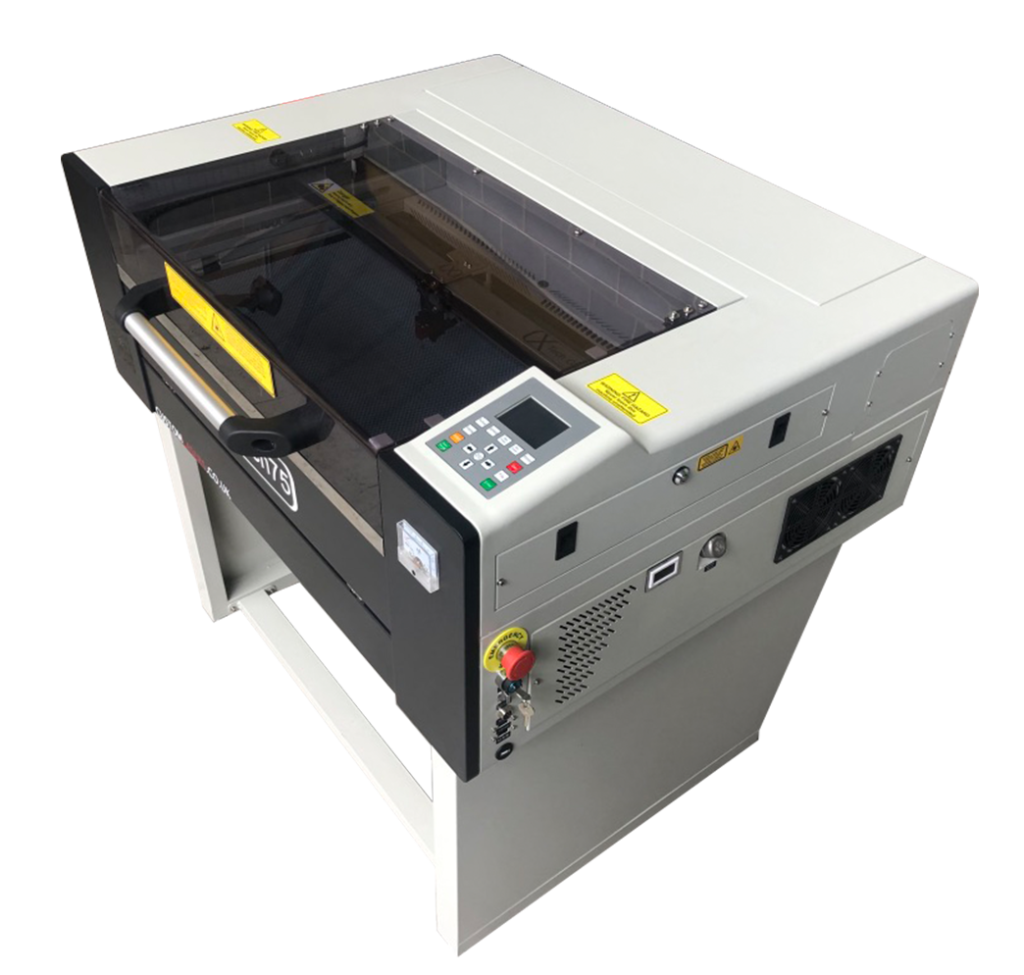

NeXGen75

| Work Area 700 x 500 |

| Wattage 40 to 80 watts |

| Max Engraving Speed 1200 mm/s |

| Max Scanning Precision 4000dpi |

| Location accuracy 0.01 mm |

| Machine Size 1100 x 845 x 480 (without stand) |

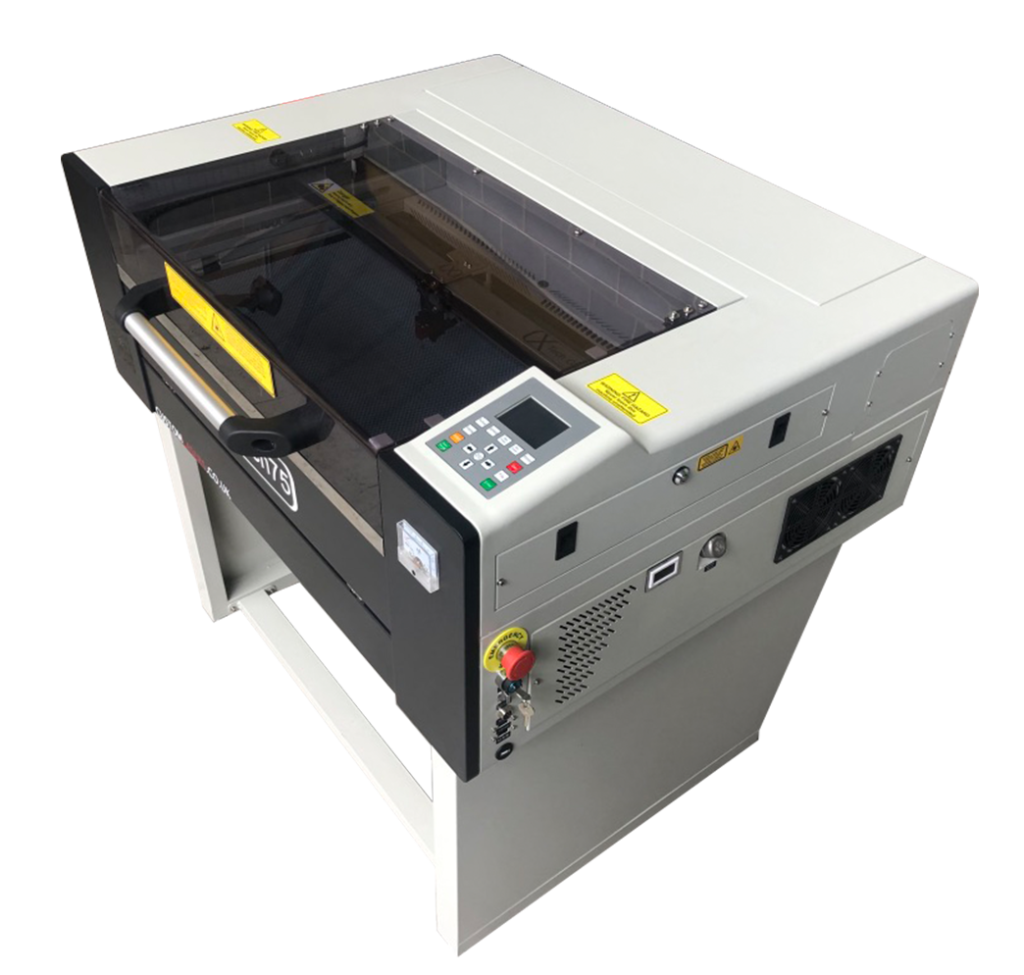

NeXGen96

| Work Area 900 x 600 |

| Wattage 40 to 180 watts |

| Max Engraving Speed 1200 mm/s |

| Max Scanning Precision 4000dpi |

| Location accuracy 0.01 mm |

| Machine Size 1300 x 1012 x 514 (without stand) |

THE ONE DESIGN

The NeXGen range has everything you need built into its design.

Inbuilt Air assist.

Inbuilt Extraction.

The cooling system is also built into the machine, so no tubs of water and pond pumps required.

Great thought has been put into image processing and workflow. Choosing the most compatible software for file transfer, meaning the NeXGen system accepts more file types and can work seamlessly with a majority of the mainstream design packages.

THE ONE DESIGN

The NeXGen range has everything you need built into its design.

Inbuilt Air assist.

Inbuilt Extraction.

The cooling system is also built into the machine, so no tubs of water and pond pumps required.

Great thought has been put into image processing and workflow. Choosing the most compatible software for file transfer, meaning the NeXGen system accepts more file types and can work seamlessly with a majority of the mainstream design packages.

STANDARD FEATURES

X Tech Guide Rail System has been designed to increase speeds, reduce machine chatter and protect the bearings and guild rails for added longevity. The ultra-wide belt and pulley system has been synchronised with the geared drive train and lightweight laser head to produce some amazing engraving and cutting speeds. The I beam rails work with the belts to enclose and protect the running gear. This reduces maintenance and increasing the life of the parts.

All mirror mounts come with Tight Lock, a duel tightening system. This means that once we have calibrated your machine you shouldn’t have to touch the mirrors, other than to clean them.

LASER HEAD ASSEMBLY

Light weight laser head – to improve acceleration and deceleration speeds by lowing G forces.

Focus Ram Autofocus – for accurate focusing.

Tight lock adjusters – virtually eliminating your machine going out of alignment.

The inline red dot laser pointer not only helps you position the laser but is also used for checking the alignment of the mirrors. Having the red dot laser pointer mounted in the back of the machine instead of on the head removes added weight, which in turn reduces G force. This also eliminates the common problem of broken red dot wires.

Remove the risk of fire – there is no need to burn masking tape in front of the mirrors to check alignment.

LASER HEAD ASSEMBLY

Light weight laser head – to improve acceleration and deceleration speeds by lowing G forces.

Focus Ram Autofocus – for accurate focusing.

Tight lock adjusters – virtually eliminating your machine going out of alignment.

The inline red dot laser pointer not only helps you position the laser but is also used for checking the alignment of the mirrors. Having the red dot laser pointer mounted in the back of the machine instead of on the head removes added weight, which in turn reduces G force. This also eliminates the common problem of broken red dot wires.

Remove the risk of fire – there is no need to burn masking tape in front of the mirrors to check alignment.

WORKING AREA

Motorised z-axis and interchangeable work platforms, making it easy to quickly change from the cutting table to engraving table.

Additional spike lifters have been included to eliminate flashback when cutting thick materials.

A level bed is critical to the whole laser process and is often overlooked. The NexGen laser systems bed is fully calibrated and fixed, giving true level focus from head to bed across the entire platform.

CROSS CONNECTIVITY

Connectivity has never been so easy. Communicate with your machine through USB, RJ45 network or simply connect to the NeXGen via WIFI. You can also transfer files via memory stick.

Connecting multiple machines to one PC. Simply select the machine you wish to transfer files too in the software. Eliminating the need for multiple PC’s.

CROSS CONNECTIVITY

Connectivity has never been so easy. Communicate with your machine through USB, RJ45 network or simply connect to the NeXGen via WIFI. You can also transfer files via memory stick.

Connecting multiple machines to one PC. Simply select the machine you wish to transfer files too in the software. Eliminating the need for multiple PC’s.

MAC & WINDOWS COMPATIBLE

The NeXGen laser system isn’t locked to a particular operating system and will work on MAC, Windows or Linux OS. Which allows you the freedom to choose an operating system that best suits your workflow.

LIGHTBURN SOFTWARE

Lightburn comes as standard. Being one of the best laser control software available, we decided to have Lightburn as the standard controller for all of the NeXGen range. Lightburn has an enthusiastic team of developers who are constantly updating and advancing the product to new levels of control, meaning you are always one step ahead.

You will receive the full package with 12 months subscription and updates, after which you can choose to renew your subscription and receive the updates or just using the software as is, without any charge.

LIGHTBURN SOFTWARE

Lightburn comes as standard. Being one of the best laser control software available, we decided to have Lightburn as the standard controller for all of the NeXGen range. Lightburn has an enthusiastic team of developers who are constantly updating and advancing the product to new levels of control, meaning you are always one step ahead.

You will receive the full package with 12 months subscription and updates, after which you can choose to renew your subscription and receive the updates or just using the software as is, without any charge.

WARRANTY

A full 12 months onsite warranty comes with all installed NeXGen laser systems. This only excludes consumables. Also included is full telephone and email support for the lifetime of ownership.

MEETING EU/UK REGULATIONS

Meeting all EU and UK regulations and compliant with EN BS 60825-1. Making the NeXGen laser system ideal for large, medium and small businesses. Its compact, safe and easy to use design also means it is well suited for the educational environment such as schools, colleges and universities.

MEETING EU/UK REGULATIONS

Meeting all EU and UK regulations and compliant with EN BS 60825-1. Making the NeXGen laser system ideal for large, medium and small businesses. Its compact, safe and easy to use design also means it is well suited for the educational environment such as schools, colleges and universities.

OPTIONAL EXTRAS

The camera is primarily used to scan awkwardly shaped objects for accurately aligning cuts and engraving. You can also use the camera as an extra set of eyes to keep a watch of the machine via your monitor or adding an extra monitor to the machine.

Rotary attachment for engraving cylindrical objects.